Newstar Advantage

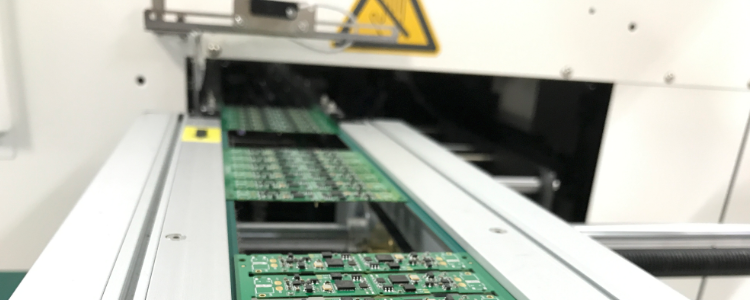

Newstar has 6 fully automatic SMT processing production line and two professional production line, SMT capacity is 8 million point per day, over 50 employee, administrative staff has 10 years experience in SMT industry, the key members were graduated from institutions of higher learning. Strong team is the foundation of providing quality and efficient services to customers, so we spare much effort in team building. In the future will also attract more senior talents to join our team, make Newstar a good patch processing supplier, to create greater value for our customers.

SMT chip processing is to process bare PCB boards and mount electronic components on the PCB. This is a popular electronic processing technology today, because electronic components are getting smaller and smaller, and gradually replace DIP plug-in technology. The SMT placement process can be divided into pre-process and in-process. Before the start of SMT chip processing, it is necessary to prepare various PCB file materials, board data (Gerber), material list (BOM) and auxiliary materials, etc. These are the basis of SMT chip processing. After the preparation is fully completed, SMT is performed.

Process capability of SMT chip processing

We also provide PCBA chip processing solutions, supporting lead, low-temperature lead-free, high-temperature lead-free, red glue processes in SMT process technology, and can be mounted on 20mm*20mm to 420mm*500mm size PCBs, with the smallest package component 01005. Supports the mounting of integrated circuits such as BGA, PQFP, PLCC, SOP, SOJ. Fuji high-speed placement machine, multi-function machine, AOI optical detector, eight-zone reflow, wave soldering and other equipment to support capacity and process quality. We are very strict in the control of the process, including the stirring time of the solder paste, the scrubbing time of the steel mesh, the check of the first piece, the check of the loading, and the IPQC Inspection. We strictly follow the ISO9001:2008 system standards, and continue to improve, the straight-through rate of our old model can reach more than 99.99%, the average straight-through rate is above 99.9%. At the same time, it can also support the patch of flexible circuit board FPC. During the SMT placement process, our engineers will summarize and analyze the manufacturability report, and raise the issue of defects in the production of the board (which easily lead to an increase in the defect rate of the SMT chip package), which is convenient for promoting the optimization of the board design process. The overall help customers improve the electronic assembly through rate.

Quality Control of SMT Processing

We cherish customers’ quality requirements of SMT processing, follow the international IPC electronic acceptance criteria, strictly implement the SOP operation process, and strengthen the SMT processing quality. Newstar has accumulated rich experience in SMT chip processing technology, and common problems such as cold solder joint and material shortage can be effectively controlled, because we have adopted a standard management system based on international IPC and ISO9001 to ensure products in accordance with process execution standards, reasonable post setting, and clear responsibilities. IQC and IPQC quality control is in place. In the long-term experience of serving foreign customers, the company has a strong sense of quality from the management to the grassroots employees, and does not let any potential problems flow into the next workstation, aiming to become the leader of Shenzhen SMT patch processing factory, and continue to provide refined customers service.

1. The quality control department is unqualified or does not meet the responsible department or the non-discovery department, etc., and the problem-resolving organization is reviewed, and a problem-solving team is established.

2. Propose preventive measures for potential adverse or non-conforming items, such as testing, simulation, data analysis, QC techniques, etc., and appropriate error-proof design and quality control.

3. For the bad or non-conformities that have occurred, the problem-solving team re-evaluates and verifies the relevant technologies, quality standards or improve the process or design level, and confirms whether all products or processes related to the quality system have similar problems and comprehensive Prevent and propose solutions.

Lead Time of SMT Processing

For small SMT processing, generally only need 2 to 3 days, quick proofing to allow customers to see the sample in the first time, shorten the time from product design to production.For different batches of smt processing, lead time is different. In standard PCB production conditions, the length of the lead time is determined by the batch size

Price of SMT Processing

The SMT processing price is calculated according to the solder joint. At present, the price of solder joints varies from 0.008 to 0.03 rmb / solder joint, depending on the process difficulty of SMT processing and SMT manufacturers’ decision on the quality control requirements and capabilities of the patch. Often cheap, there may be no testing links, no material inspection links, the quality of the entire batch of SMT patches is difficult to guarantee, product consistency and reliability will also have a large late hidden dangers. Manufacturers with a slightly higher price of the patch will have a quality control process and a better delivery cycle and service. Customers choose SMT patch suppliers based on their own situation.